A tank's overall performance during combat does not only depend on the technical characteristics. It also depends on the psychological, emotional and biological factors of the crew and their given tasks.

One way to ease the crew's operating stress is to automate certain processes of the vehicle. But in some cases, this solution does not work, due to the higher qualification requirements for the operation. This issue is more significant when the overall operation complexity of certain modules becomes more delicate and requires highly qualified personnel. As a result, this increases the stress level of crew members. This may be less of an issue with a highly trained crew member but on the other side, the overall performance factor of a crew member heavily depends on the surroundings in which he performs, especially in extreme conditions, such as the crew compartment of any AFV, which can become a harsh operating climate due to the fluctuating microclimate.

A vehicle's microclimate depends on surrounding natural factors, such as temperature, air humidity, solar radiation, wind speed and barometric pressure. These conditions can change throughout the day and, as a result, cause microclimate fluctuations inside crew compartments. Additionally, internal equipment radiates heat, significantly decreasing crew comfort, especially in hot climates. Crewmembers cannot cool themselves, resulting in drastic performance drops.

Tank microclimate during marches

In the 1980's a variety of tests were conducted to evaluate the microclimate inside MBTs during prolonged convoys. A T-72 and T-80 of unspecified variants were chosen. Surrounding atmospheric temperature ranged between 13°C-24°C and averaged at around 19°C. The temperatures inside the crew compartment reached approximately 31°C during the day and would drop to around 29°C at night. The driver's position would experience similar values of 29°C during the day and 28°C at night. Internal temperatures would exceed the surrounding atmospheric temperature by 9°C-11°C. This was due to solar radiation heating up the metal. Along with increased internal temperatures, high humidity levels would form humid zones, accumulating due to lacklustre air circulation and ventilation.

Soviet MBTs like the T-72 and T-80 utilised a filter-ventilation system, which provides ventilation by pumping clean air into the fighting compartment. Due to the increased air pressure generated inside, the system also assists with removing toxic gas build-up after firing the main cannon and coaxial machine gun. This is done with higher air pressure inside the tank. After firing the main gun, the breech opens resulting in the higher-pressure air escaping through the gun barrel and ventilating the compartment. This phenomenon would also work on tanks that used a rear turret hatch to dispose of spent casings.

To stabilise internal microclimates and their effects on the human body the integration of an air-conditioning system can be done. Soviet design bureaus have proposed a variety of air-conditioning system designs for MBTs and IFVs.

Turbo-cooling air-conditioning systems for tanks with gas-turbine engines

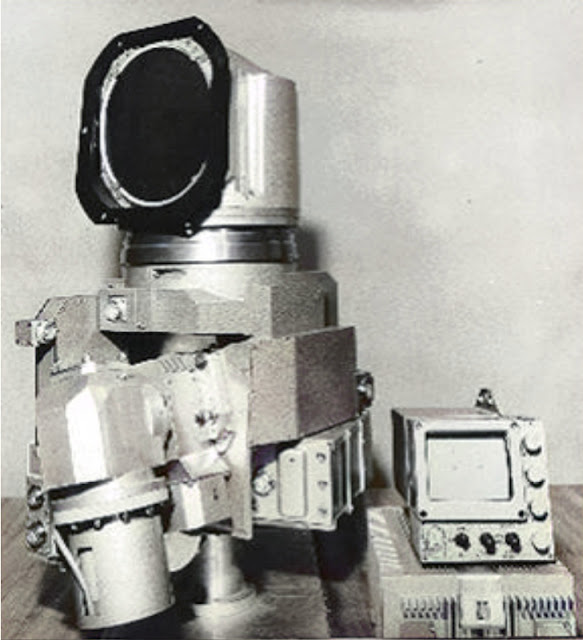

One of the propositions was to mount a turbo-cooling air-conditioning unit on the T-80 MBT. The idea was to divert airflow from the air-filtration unit into a turbo-cooling unit. The first iteration of the unit could provide 300kg/h of air at 0,6-0,8MPa of pressure and achieve a maximum temperature of 400°C. The cooling/heating performance of the unit was determined by the climates in which the vehicle operated.

Air conditioner cooling capacity was determined by desert operating conditions and Transbaikalia winter thermal conditions. The calculations showed that to maintain a microclimate in the tank's combat module following medical and technical requirements, the air conditioner must provide cooling power of 3.5 kW and heating power of 9.6 kW, which is about 20%-25% less than the data obtained through stationary heat transfer prediction. This made it possible to adopt a more reliable turbo-cooled air conditioning system. The turbo-compressor of the engine supplies compressed air to the loop.

It was determined that at an ambient temperature of 40°C, the oil temperature in the engine lubrication system increased by 2°C and did not exceed the permissible value of 140°C and the transmission oil temperature increased by 5°C. This results in a total cooling air consumption of 200 kg/h-205 kg/h distributed as follows: driver 80 kg/h, gunner 48 kg/h, commander 77 kg/h. Across the crew positions, the temperature ranged from 22-26 degrees Celsius. A further set of tests was carried out in the Turkmen SSR with ambient temperatures ranging from 32°C to 44°C and humidity levels ranging from 20-40%.

.jpg) |

1 - hot air streams; 2 - line for hot air; 3 - line for cooled air; 4 - turret air supply unit; 5 - turbo-cooler; 6 - transmission oil radiator; 7 - heat exchange unit above radiator; 8 - filter; 9 - electromagnetic valve; 10 - warm air engine air diversion valve; 11 - engine oil radiator; 12 - heat exchange unit underneath radiator; 13 - regulating shutter; 14 - turret air supply direction; 15 - control valves

|

Installing a turbo-cooled air conditioner on the T-80 tank has proven to significantly improve microclimate conditions. The temperature for each crew position ranged between 28°C-34°C. Without an operational air-conditioning unit, the temperature would reach 50°C. Along with cooling tests, heating trials were carried out in the Transbaikalia region at temperatures up to -45°C. Within 20-30 minutes, the vehicle temperature rose and continued to rise. Each tanker regulates the temperature individually.Microclimate research for T-80 tanks with air-conditioning units

A T-80 was equipped with an air-conditioning unit. Additionally, personalised cooling vests were designed to accommodate localised body cooling.

|

| Image 1. 1 - Outer layer; 2 - Inner shell; 3 - Internal holes inside of inner shell; 4 - Hook-and-eye zipper; 5 - Connector; |

The air-conditioning system uses compressed air from the gas turbine's turbocharger. The system comprises a turbo-cooler, thermal exchange unit, distribution devices and tubing. The air from the gas turbine supercharger is temporarily cooled using thermal exchange units. The compressed air temperature is lowered through adiabatic expansion inside the turbo cooler using a 1-stage turbofan. Excess energy is diverted and dampened by a ventilator.

Individual vests are connected to supply tubes using a quick-release connector. Each vest has 2 air-tight shells, allowing cold air to travel through the air-tight space. The inner shell has 2mm thick holes that let out cold air and cool the skin. The amount of cold air supplied can be regulated using valves.

Testing was conducted in the Turkestan Military District. Phase I was carried out to collect the filter ventilation system performance characteristics. Phases II and III were carried out to collect information on the crew and their temperatures with the AC unit. Several desert trials lasted around 4,5 hours and covered a distance of 48,4 km. The vehicles performed at their maximum capacity with completely shut hatches.

Phase I trials showed that air temperatures inside the T-80's combat compartment reached 35°C/38°C, resulting in a stressful environment. Temperatures peaked at a maximum of 39,3°C/39,9°C and relative humidity was 76%. The crew experienced a temperature gain of 60 kcal. Under these conditions, crew performance drastically drops and the average sustained work duration reaches 0,7/0,8 hours.

The filter-ventilation system reduces the crew's temperature loss using convection, which means that evaporation is the only way of reducing temperature/humidity. During trials, it was determined that crewmembers would lose around 1,6kg of sweat and require 1,5 litres of water. Due to the rather hostile internal environment, the average time needed to stabilise body temperature was 1-1,5 hours.

The integration of an AC unit confirmed that the crew could operate in hot environments without discomfort for 6-8 hours. During trials, it was assessed that with an operational AC unit, the average vehicle mobility increased by 16%-23%. Mobility in this case was considered how fast certain crew tasks were completed.

|

Gathered results after a 4-hour march

(- in Loss of water cannot be measured during initial trial start) |

Certain values were chosen to determine if a crew member could still perform his duty or be classified as "incapacitated". Several maximum values were chosen: Body temperature = 38°C, heart rate = 140 BpM, and generation of heat not more than 100 kcal. With a turned-on AC unit operating in ambient temperatures ranging between 34°C-38°C, the cooling vests provided stable temperatures for all 3 crew members.

|

| The temperature of supplied air through cooling vests for each individual crew member |

T-80 tanks fitted with AC units can provide crews with standard temperature and humidity conditions. With direct feedback ranging between comfortable and warm. The most effective solution is the supply of cooled air through a cooling vest and ventilation in the general breathing zones. Integrating an AC unit powered by a tank's gas turbine turbo compressor can efficiently provide the crew with optimal conditions to perform their necessary tasks at ambient temperatures exceeding 30°C.

Along with the T-80 MBT undergoing a variety of testing with the integration of AC units, the T-72 was also used as a testbed to conduct programs focused on integrating AC units.

Prototype air-conditioning unit for the T-72

Tests were conducted on several hermetically sealed T-72 tanks in the southern parts of the USSR where ambient temperatures of 29°C would cause internal temperatures to reach 35°C. In addition to ambient temperatures raising internal values, an active filter-ventilation unit and a turned-on stabiliser would heat the inside of the vehicle to 39°C, which was above the 33°C GOST temperature value permitted for 6 hours of operation.

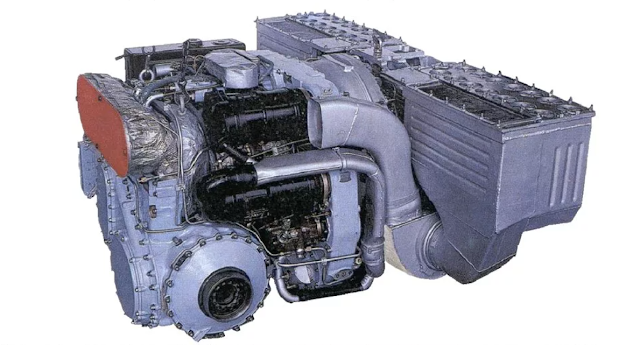

To solve this an air-conditioning unit was proposed, which used a condenser mounted above the fuel-cooling radiator. The unit was named M-50 and used an FA-50S axial piston compressor. The unit was made to meet the GOST criteria for AFV microclimate without critically retrofitting tanks.

|

| FA-50S axial-piston compressor |

The compressor weighed 20kg, had a cooling capacity of 5000 kcal/h, and used Freon-22 as the cooling liquid. The entire unit used corrugated hoses for the loop. The aforementioned condenser was mounted in the available space between the radiator core and the radiator's fins.

The AC unit could perform in climates where temperatures range between 35°C and 37°C, the engine operating at higher loads also allowed the unit to function above ambient temperatures of 37°C. The M-50 has 3 air purification units with axial ventilators. One unit replaced the heating unit, the second is mounted behind the driver, which requires some internal components to be moved around and the third is mounted next to the AFV's main air-filtration unit. In total 800m^3/h of air was consumed with temperature drops between 5°C-10°C.

Trials showed that the compressor had insulation issues which led to freon leakage. It was proposed to use magnetic сoupling to prevent further leaks caused by persistent vibrations. The 3 air purification units caused uneven freon circulation in the loop, hindering cooling performance.

A solution was to reduce the total amount of air purifiers to 2, one with a cooling capacity of 4000kcal/h and the other with 2000kcal/h. It was considered that each heat-exchange unit could differ in dimensions depending on where it is mounted. The entire loop was to be fitted with soft tubing, which allowed for easier servicing and prevented loop deterioration from vibrations.

In practice, the M-50 air-conditioning unit was tested at atmospheric temperatures between 25°C to 31°C. As a result, it was determined that with the stabiliser and filter-ventilation unit, the interior of a T-72 would reach temperatures of 35°C-40°C. With an active air-conditioning unit these values would drop to 22°C-26°C. The benefits, which the AC unit provided overshadowed the minimal performance losses of the engine cooling system. Engineers attempted to determine the efficiency of the unit when used as a heating unit since it was possible to obtain heat from the compressor and the engine cooling system.

To summarize, all these air-conditioning systems were created to solve the problem of difficult microclimate control inside tanks. The Soviet Union continued to trial and patent other systems. In the end, none of these systems were accepted as standard onboard packages for T-72 and T-80 tanks. After the collapse of the USSR and an opening in the export market, some export variant models of T-90 tanks have been equipped with AC units. Other tank variants that are intended for export also offer AC unit integration for customers operating in hot climates. Such models will be covered in an upcoming article.

References:

- Вестник бронетанковой техники, № 2, 1984 - "Микроклимат в танке на марше"

Вестник бронетанковой техники, № 4, 1985 - "Опытная система кондиционирования воздуха для танка Т-72" - Вестник бронетанковой техники, № 12, 1988 - "Турбохолодильная система кондиционирования воздуха танка с газотурбинным двигателем"

- Вестник бронетанковой техники, № 11, 1989 - "Исследования микроклимата в танке Т-80 с системой кондиционирования воздуха"

- Виктор Ранцан YouTube channel

.jpg)

Comments

Post a Comment