Soviet Union/Russian thermal sight development history

Related topics: "AGAVA" - "AGAVA-2 "and its confusing history

Thermal imagers were classed as; Gen-I, Gen-II and Gen-III. Gen-I sights featured the most basic technology due to them being the first of their type. Gen-II sights commonly improved on Gen-I technology by utilizing similar but more refined technical advancements or used completely new methods. Gen-III sights used new advanced technology that is no longer associated with Gen-II and additionally features new materials for photo-elements and ways of processing.

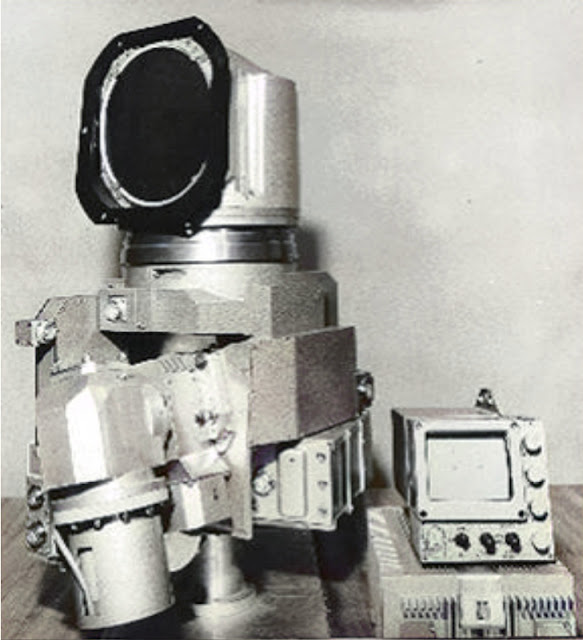

Image 1 (For full resolution open the image in a new tab)

The table above represents domestic Soviet and early Russian thermal modules/sights.

Generations are split into 3 different time periods, Gen-I sights primarily appeared in the 1980s but also made appearances in the 1990s, Gen-II sights appeared in the 1990s and Gen-III sights appeared in the late 1990s and 2000s.

Gen-I systems: Utilize linear photo-receiver with 2 types of indicators; based on ICRT and LED, and 3 types of standard samples - GHM, GBS and TEO (Thermoelectric cooler), scanning is performed on 1-2 coordinates, ability to have 2 different FoVs.

Gen-II systems: Utilize Gen-I unified photo-receivers with photo-element resolutions of 2x10, 2x16, 2x32 and Gen-II photo-receivers with formats of 2x256 (4x128), 4x288. Image display to the normal TV signal, electronic post-processing module. Optical-mechanic scanning on 1 or 2 coordinates. Usage of inbuilt automatic elements controls for sensitivity and stability, a small-sized closed-loop Split-Stirling system, microprocessors for adjustment of electronic parameters and an inbuilt interface.

Gen-I systems: Utilize linear photo-receiver with 2 types of indicators; based on ICRT and LED, and 3 types of standard samples - GHM, GBS and TEO (Thermoelectric cooler), scanning is performed on 1-2 coordinates, ability to have 2 different FoVs.

Gen-II systems: Utilize Gen-I unified photo-receivers with photo-element resolutions of 2x10, 2x16, 2x32 and Gen-II photo-receivers with formats of 2x256 (4x128), 4x288. Image display to the normal TV signal, electronic post-processing module. Optical-mechanic scanning on 1 or 2 coordinates. Usage of inbuilt automatic elements controls for sensitivity and stability, a small-sized closed-loop Split-Stirling system, microprocessors for adjustment of electronic parameters and an inbuilt interface.

Gen-III systems: Utilize microbolometer matrix (U3000) with formats of 320x240 or additional formats such as 512x256, and 328x245. Photo-element size of 51x51 μm. No longer using optical-mechanic scanning, the diameter of receiver optics ≤ 300mm.

-----------------------------------------------------------------------------------------------------------------------------

Tank Sights

"Progress/Progress-M" was the first sight of its series, featuring a matrix with 100 photo elements composed of GeHg and each element measuring 0,1x0,1 μm. "Progress" was 1 of 3 sights made during the 80s to feature 2 different FoVs; Wide (7,5x12) and narrow (2,5x4). Also featured one of the best identification ranges of 2,3-2,6km compared to other sights such as "AGAVA" with 2,0km or "Posobiye" with also 2,0km. The sight could operate in an 8μm-12μm spectral range.

"Progress-2" In the early 80s, on the instructions of the Ministry, M. M. Miroshnikov was assigned to lead the direction of creating specialized thermal imaging devices in support of new manufacturing abilities. The "Progress-2" TI Sight (NP-50) was created. The entire system (optics, electronics, accessories) was made using domestic technology and parts. An original digital signal processing system was created in the laboratory of V. I. Solovyov. Together with the array of photodetectors a new submatrix IR receiver (2x48 el.) using Ge: Hg (mercury-doped germanium was supplied by SIoAO (State Institute of Applied Optics)) was created. The matrix with "optical traps" was created by the (VSOI) Vavilov State Optical Institute. For the first time, a cooling system operating on the "Split-Stirling" cycle was used, cooling the photo-receiver to 30 K. VSOI participated in the creation of this system and helped SPA "Sibkriotekhnika" manufacture the sight.

NP-50 featured a new photo receiver "Progress-2FP" with a 4x48 photo-element layout with each element composed of Ge:(Hg). As with the Gen-I sight, this Gen-II sight was also one of the most powerful out of the Gen-II segment. Having 2 variable FoVs; Wide (9x12), Narrow (3x4). The identification range was also improved, reaching 3,2km and outperforming "AGAVA-2" identification range of 2,3km. The identification range could vary depending on the weather. The sight could operate in an 8μm-12μm spectral range.

In 1988-89 the sight was tested, and all the documentation and information was sent to JCS "Peleng" for the preparation and mainstream production of the sight.

In 1988-89 the sight was tested, and all the documentation and information was sent to JCS "Peleng" for the preparation and mainstream production of the sight.

"Progress-2M" was the last sight made part of the series. Considered to be an advanced Gen-II sight, it featured the same photo element composition but improved on the matrix resolution of 500x384 with a 48x2 linear scanning process. Magnification was also improved The sight could operate in an 8μm-13μm spectral range.

"Progress-2M" characteristics.

It is worth noting that all these 3 sights were not made for serial production, unlike the "AGAVA" series of sights. Hence sights like "Progress" were far more advanced, containing higher performance parts that require advanced manufacturing equipment, unlike serial production sights that are supposed to be made in larger quantities.

In the end, "Progress"/"Progress-M"/"Progress-2"/"Progress-2M" TI sights didn't get accepted into any type of service and remained as testing units, this is potentially related to poor visibility and target identification at small-medium ranges. Since the 1990s it is been considered to integrate thermal imaging sights into military equipment like the "Malyutka-2" ATGM complex. Portable or vehicle-mounted AT weapons weren't the only weapons considered to be upgraded. Due to Russia operating several different MBTs like T-72/T-80/T-90 tanks, it was considered to improve their FCSs with thermal imaging sights. Additionally, vehicles such as the "Shturm", "Buratino", "Krasnopol", "Bakhcha" and many others were considered to be upgraded.

In 1999 it was decided to create a group of unified thermal imaging sights for in-service equipment and for equipment in a prototyping stage. These would be TIC (Thermal Imaging Channels) and this series of channels would be separated into 3 internal Generations.

TVK-1 channel made using a unified Gen-I phot-receiver with a 2x32 photo-element array.

TVK-2 channel made using a Gen-II photo-receiver with either 2x256 or 4x288 photo-element array.

TVK-2 channel made using a Gen-II photo-receiver with either 2x256 or 4x288 photo-element array.

TVK-3 channel developed using uncooled microbolometer photo-receiver matrices.

While designing the assembly of the TVK-1 it was considered to utilize already created thermal imaging sights such as the 1PN79-1 and its assembly format in units such as the "Shturm", TOS-1. Considering the flexibility of the 1PN79, new assembly procedures have been created to assist the creation of a small factor thermal imaging device that would support the TV display standard and be compact enough for vehicles that use the "Bakhcha-U" CM, or in T-72/T-80/T-90 tanks.

The transfer of an image into TV format was done by transferring the image using LED indicators onto the inbuilt sight interface of the vidicon unit. As a result, certain characteristics have been achieved; varial FoV of Wide (2,3x3,0) and Narrow (3,9x5,2), the diameter of the receiver optic was 100, equivalent focusing distance of 240mm and 140mm. a photo-receiver matrix with a 2x32 array showed its maximum spectral range sensitivity of 6·10 ̂10 Watts ̂-1 · sm · Hz ½ offering a temperature sensitivity of 0,25 and 1,0 K on varial median frequencies of 2,0 and 3,0 mRad ̂-1, which resulted in a detection range of 2,6km-2,8km. In comparison to an experimental 1PN79 sight with a 64x photo-receiver "Weightlessness 64TA" had a detection range of 2450m while a 1PN79 with a 32x photo-receiver FR204M had a detection range of 2200m.

The transfer of an image into TV format was done by transferring the image using LED indicators onto the inbuilt sight interface of the vidicon unit. As a result, certain characteristics have been achieved; varial FoV of Wide (2,3x3,0) and Narrow (3,9x5,2), the diameter of the receiver optic was 100, equivalent focusing distance of 240mm and 140mm. a photo-receiver matrix with a 2x32 array showed its maximum spectral range sensitivity of 6·10 ̂10 Watts ̂-1 · sm · Hz ½ offering a temperature sensitivity of 0,25 and 1,0 K on varial median frequencies of 2,0 and 3,0 mRad ̂-1, which resulted in a detection range of 2,6km-2,8km. In comparison to an experimental 1PN79 sight with a 64x photo-receiver "Weightlessness 64TA" had a detection range of 2450m while a 1PN79 with a 32x photo-receiver FR204M had a detection range of 2200m.

The TVK-1 utilized a serial production miniature vidicon unit LI437 with a resolution of 500 lines (centre) and 400 lines (corners).

The transition of domestic TI sight developers to produce submatrix photo-receivers (format 2x256(4x288)) with small form factor enclosed Split-Stirling cooling cycles together with electronic processing units allowed a faster development of TI devices which in result mitigated the technological gap between domestic and foreign TI tech.

In domestic literature about TI development, it's been pointed out that there was the development of non-cooled photo-element receivers based on bolometric matrices with a 64x64 photo-element array and the element being 76x76 μm in size, manufactured using micromechanical silicon technology.

In the 2000s, several Russian institutes started developing newer generation TI systems that would feature different matrix compositions and formats.

Main parameters of focal IR matrices for Russian-made thermal imaging devices

JCS "Orion" makes matrices composed of Cd-Hg-Te (solid solution of cadmium-mercury-tellurium) using 128x128 or 384x288 format resolutions with each pixel measuring 35x35μm with a temperature ceiling of 80°C and operates in an IR spectrum of 8-10,5μm. Additionally making matrices composed of InSb (Indium antimonide) with a similar 128x128 format resolution with each pixel measuring at 50x50 μm and operating in an IR spectrum of 3-5 μm.

CJSC "Matrix Technologies" produces matrices composed of PtSi (Platinum silicide) using 3 different format resolutions, while 2 are commonly standardized between other companies, they achieved a 512x512 format resolution with each pixel measuring 14x14μm.

CRI "Electron" produces matrices composed of PbS (Lead Sulfide) using 128x128 format resolution with pixels sized at 60x60μm a temperature sealing of 80°C and operate in an IR spectrum of 1,5-4μm. Additionally also produces matrices composed of PbSe (Lead Selenide) with a format resolution of 256x256 that operates in an IR spectrum of 2-6μm. Or making the same resolution format but producing the matrix based on PbSnTe (Lead tin telluride) that has a temperature ceiling of 25°C and operates in an IR spectrum of 6-14μm.

Lastly, JCS "Orion" also produces entire TI modules such as the FEM18 optoelectronic module utilizing a cooled matrix composed of Indium antimonide photo-diodes with a 640x512 format. This module operates on an IR spectrum of 3,5-5,0μm

References:

- V. V. Korotaev, G. S. Melnikov, S. V. Mikheev, V. M. Samkov, Yu. I. Soldatov FUNDAMENTALS OF THERMAL IMAGING, Saint Petersburg 2012 -- В.В. Коротаев, Г.С. Мельников, С.В. Михеев, В.М. Самков, Ю.И. Солдатов ОСНОВЫ ТЕПЛОВИДЕНИЯ Санкт-Петербург 2012

- Methods and means of monitoring the characteristics of thermal imaging devices and systems. Moscow (Russian State Library) 2005 -- Методы и средства контроля характеристик тепловизионных приборов и систем, Москва (Российская государственная библиотека) 2005

- Optical Magazine 2017 -- Оптический Журнал 2017

- Vidicon LI437-1 Passport - Видикон ЛИ437-1 Паспорт

- Radiation receivers and detectors Baranochnikov M. L, Moscow, 2012 -- Приемники и детекторы излучений Бараночников М. Л, Москва, 2012

- Army-2021 JCS "Orion" Thermal Sight brochures

----------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------

Comments

Post a Comment