T-72/T-90 and T-80 engine cooling

This article is a simplified approach to explaining how Soviet/Russian engines are cooled.

The T-72 and T-90 series of vehicles are equipped with

standard V-84 and V-92 engines. Both engine types feature an enclosed liquid

cooling loop with active air-cooling circulation facilitated by a fan.

The T-80 and its GTD series of engines, including the GTD-1000 and the GTD-1250, utilize active air and oil cooling for the turbine.

DETAILED LOOK AT THE T-72/T-90 ENGINE COOLING LOOP

|

| T-72 engine cooling loop and layout |

The T-72 uses a closed liquid loop system to cool the engine and two oil lubrication tanks. Coolant heated by the engine is divided into three streams within the engine bay:

The main coolant stream is pumped into the radiators and

cooled with atmospheric air, which is pulled into the engine bay using a

ventilator. After passing through the radiators, the coolant enters the engine

water pump.

The second stream flows towards various components, such as the coils inside the engine's main oil lubrication tank and the hydraulic control and lubrication system tank, which lubricates the transmission. The flow also reaches the heating unit, which is mainly used during winter.

The third stream circulates through the drainage and compensation circuit, which is directly connected to the heads of the engine block. It also circulates through the left water radiator before entering the water pump.

|

| T-72 cooling fan drive and layout |

As for the cooling fan in the T-72 and T-90 series of tanks, the fan is powered by diverting a fraction of power from the engine. This is done with a transfer case, which transfers power from the engine to the left and right BKPs. The fan is mechanically coupled to a fan drive bevel gear connected to the transfer case. The fan has high and low operating modes. Per Vestnik data, a T-72 with a new cooling fan and inlet vanes (1984-1985), the cooling losses at high mode were 7.7% and 4.9 in low mode. Note that the % loss is from the total hp the engine outputs.

DETAILED LOOK AT THE T-80 ENGINE COOLING SYSTEMS

|

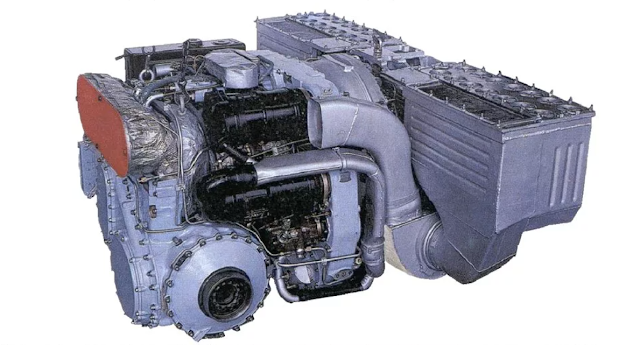

| GTD-1000T/TF and GTD-1250 air flow diagram. Red-black arrows indicate polluted air, red arrows indicate clean air circulating inside and around the engine block, and black arrows indicate sand and dust particles. More about GTD air filtration can be found here. |

|

| Diagram for the left oil radiator. The airflow principle also applies to the right radiator. |

.png) |

| Engine comparison chart. GTD-1250 cooling system power draw rated at 40 hp. From a short Soviet film about the GTD-1250. |

Lastly, turbine cooling. GTD turbines run at much higher temperatures than the V-84/V-92 series of engines. The GTD-1000T/TF and GTD-1250 are both air-cooled. Cooling air is generated by the low-pressure compressor and constantly pumped into the engine's chambers and cavities. High-pressure compressors provide large amounts of air, which fills air chambers and cavities, primarily around the combustion chamber. Air supplied by the high-pressure compressor enters the combustion chamber through the inlet slats to regulate combustion temperatures.

|

| Diagram depicting streams of air used to cool vital turbine components: low- and high-pressure turbine blades and external surfaces surrounded by cavities and chambers. |

- Вестник бронетанковой техники 1985, Сборник Но.2

- Газотурбинный двигатель ГТД-1250. Филмь - Film

- Двигатель ГТД-1000Т. Техническое описание. МО СССР. Москва 1980

- Двигатель ГТД-1000Т. Серия плакатов

- Система охлаждения Т-72

- Танк Т-72Б Техническое описание. Москва Военное Издательство 2002

- T-72 The Definitive Guide to the Soviet Workhorse". Ryan A. Then

Comments

Post a Comment