Prospective SPG R&D Program: "Uspekh"

The "Uspekh" research and development program was conceptualised in the late 1960s by OKB-3 based on a request made by the Military-Industrial Commission of the USSR in 1968 to perform R&D to create a new prospective artillery system between the 1971-1975 and its further development through 1976-1980.

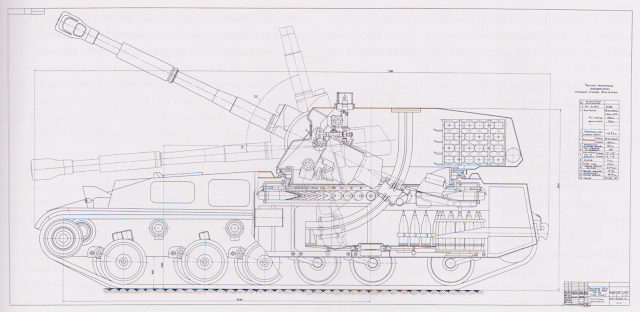

This program's first stages focused on comparative analysis of domestic and foreign artillery systems and their relative performance. In 1969, the first proposed schematics were presented by OKB-3, featuring 122mm and 152mm artillery systems. The proposed design choices followed certain criteria; improving ammunition capacity, firing range and rate of fire, improved survivability in scenarios when nuclear weapons are used and improved mobility. The designs were based on unmodified 2S3 "Akatsiya" hulls aiming to preserve the engine transmission bay, and the main armament was to use obturation with caseless munitions to reduce excess fume accumulation inside the fighting compartment.

The 122mm cannon variant had to be designed using the already existing D-32 due to a lack of existing performance material on new artillery system concepts. The fighting compartment had a similar volume as the 2S3 and was meant to store an ammunition capacity of 89 rounds compared to the 40 rounds on the 2S1 "Gvozdika". The 2-piece ammunition was stored in various places. 48 HE rounds were stored below the turret ring in a radial stowage rack, 36 rounds were stored in 2 vertical carousel racks in the back of the hull and 5 other rounds were stored on latches mounted on the right side of the hull. 72 charges were stored in the back of the turret, while the rest were stored in containers underneath the commander's and loader's seats.

Loading shells from the radial rack below the turret ring was meant to be automatic from any elevation angle of the cannon. The vehicle weight is approx. 27120kg and had a crew of 4.

|

| R&D "Uspekh" with 122mm D-32 |

The 152mm cannon variant project was split into 3 participating bureaus. OKB-3 was tasked with the hull, OKB-9 was to work on the D-67S with caseless obturation and NIMI "Minmash" was to work on shells. The D-67S differed from the 2A33 with an increased length, with an assumed firing range of 24km for HE munitions and 35km for rocket-assisted shells.

|

| R&D "Uspekh" with 152mm D-67S |

Replacing standard munition with caseless-type charges had to be done within certain criteria.

- A rigid caseless-type design that can work with an automatic loading mechanism has a lower chance of ignition during increased workload scenarios and minimal leftover residue after combustion.

- Reworked breach with inbuilt pre-ignition mechanism. This design increased the time frame for how long the breech is open, reducing the rate of fire.

- Hermetically sealed charge stowage that had increased volume displacement.

In the end, the vehicle exceeded the maximum weight specification by 837kg (28837kg) due to the larger cannon and lengthened hull. Further improvements had to be made to reduce weight but were never followed through.

- Боевые Машины УралТрансМаша, Книга Третья - Уральский Букет 1966-1989 гг.

Comments

Post a Comment