2S4 "Tyulpan" predecessor concepts by Perm Machine-Building Plant

In the 1960s, the Perm Machine-Building Plant named V. I. Lenin (now known as PJSC Motovilikha Plants) conceptualized the installation of a 240mm mortar on a BMP-1 and MT-LB chassis. The preliminary design did not utilize either chassis but instead used an Object 132 hull which at the time was in a similar weight range. Additionally, PMBP already looked into using the Object 132 hull to mount the "Uragan" MLRS system.

3 different mortar mounting options were considered.

- The mortar system is mounted in the centre of the hull and positioned to fire forward.

- The mortar system is mounted in the rear of the hull. The base plate is hard-mounted to the chassis and lifts the hull when moved into the ready position. Mortar can only fire backwards.

- The mortar system is mounted in the rear of the hull. The base plate is connected to the hull and can be lowered into the firing position. Mortar can only fire backwards.

With the 3rd design option chosen, various ammunition-loading designs were considered.

- Magazine styled loader

- Drum loader with hydraulic arm to ram shells directly into the mortar

- Drum loader with 2 mechanised drums

- Drum loader with a hydraulic lifting arm to move shells mortar shells into an assisted loading mechanism.

The last design option was chosen since it met requirements like RoF and the ability to select mortar shells before the loading sequence.

Later, the Perm Machine-Building Plant named V. I. Lenin was tasked with designing the M240-S Tyulpan and later work was passed onto OKB-3 on September 9th 1966.

Later, the Perm Machine-Building Plant named V. I. Lenin was tasked with designing the M240-S Tyulpan and later work was passed onto OKB-3 on September 9th 1966.

|

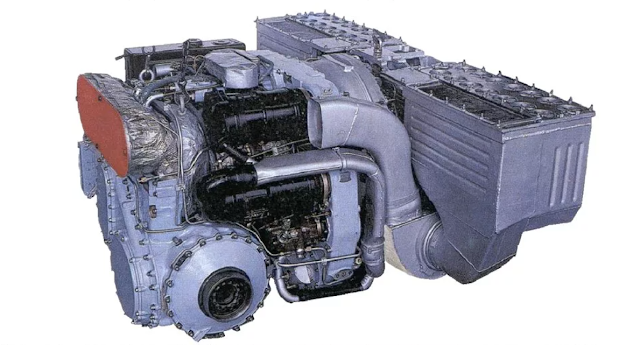

| 240mm mortar installed on a BMP-1 chassis |

|

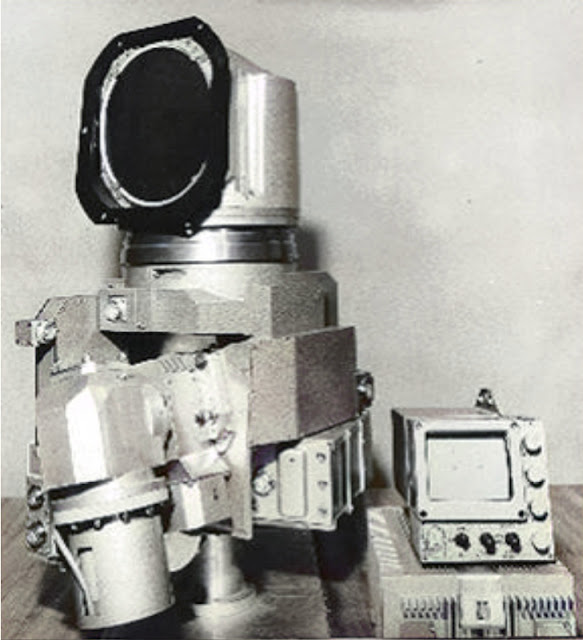

| 240mm mortar installed on an MT-LB chassis |

Scans provided by the author of the blog.

Taken from:

- Боевые Машины УралТрансМаша, Книга Третья - Уральский Букет 1966-1989 гг.

Comments

Post a Comment