Tracked dual-link transport carriers by OJSC Machine-Building Company "Vityaz"

Background

The OJSC Machine-Building Company "Vityaz" finalized the 1st building phase of its assembly plant in 1988. The proposed idea was to establish several facilities for the development and assembly of DT two-section tracked carriers part of the "Vityaz" vehicle family.

In 1982, the plant launched the DT-10P into serial production. Four years later in 1986, the plant introduced the DT-30P.

Due to the configuration of the chassis and caterpillar system, the vehicle had exceptional cross-country capabilities, allowing it to traverse different terrains such as swamps, deep snow, mud and many other poor condition areas. With these capabilities, a vehicle of this type can transport different types of cargo ranging from; military equipment, supplies, portable control facilities and many other things.

DT-10P, DT-30P dual-link amphibious carriers

The DT-10P, DT-10PM, DT-30P and DT-30PM dual-link tracked amphibious carriers are intended for transporting heavy cargo ranging from 10 tons to 30 tons.

The carriers are serviceable and preserve all performance characteristics at:

- Ambient temperatures from -50°C to +40°C

- Relative humidity of up to 98% at 35°C

- Wind velocity of up to 20m/s

- Dust content in the air up to 2g/cm^2

- Atmospheric precipitation

|

| Articulating coupling mechanism |

The turning of these carriers is enabled using an action called jackknifing which utilizes an articulating coupling mechanism that is powered and brought to motion via the usage of hydraulic rams installed on the coupling mechanism.

The DT-10P and DT-30P roadwheel arrangement is as follows:

- Front section (4x4) - Rear section (5x5) for a carrying capacity of 10 tons

- Section arrange of (6x6) for a carrying capacity of 30 tons

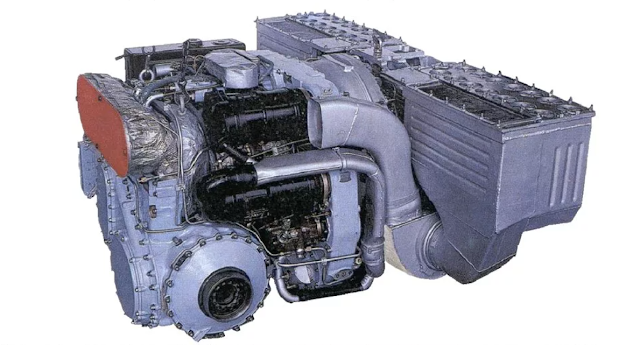

The transmission consists of a hydro-mechanical drive with intersection and inter-hub differentials, 4 onboard and 2 сonical gearboxes. The variation of the drive sprocket traction force and carrier speed is achieved through an automatic shifting and gear ratio torque converter.

These variants are based on the DT-10P and DT-30P but underwent modernization allowing them to perform better.

The transmission was also changed to use a shaft-type reinforced 4-speed hydromechanical gearbox with a matching сonical gearbox and a multi-level torque converter.

- Engine life has been improved (threefold/fourfold)

- Environmental safety (overall external noise reduced by 30dB)

- Improved fuel economy (10%-15% decrease in fuel consumption and a tenfold reduction in engine oil consumption)

- Average maximum speed increased by 25%

- Improved ergonomics

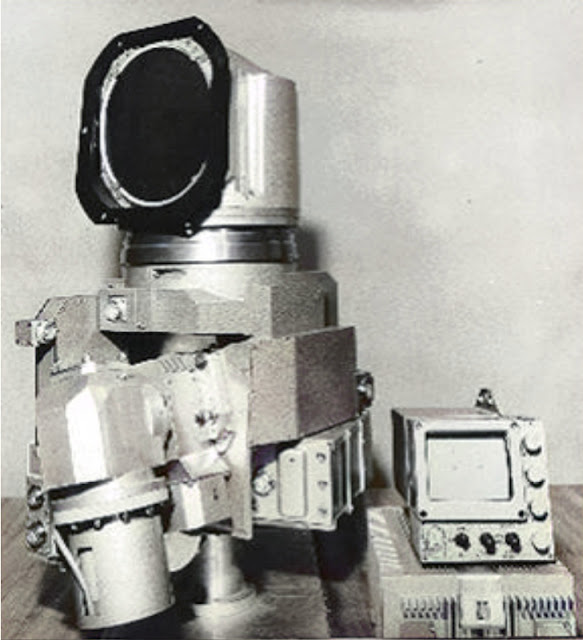

- Available protection and concealment equipment

- (5x5)x2 - for payloads up to 10 tons

- (6x6)x2 - for payloads up to 30 tons

Comments

Post a Comment